The fields described below have special functions. For a complete list of available fields, see the Lucity Data Dictionary.

Equipment ID ** |

The user-defined, unique identifier for this piece of equipment. The Equipment ID consists of two alphanumerical fields: 1) a code; and 2) a description or name. Remember: When choosing an Equipment ID, the number must be unique in order for it to represent only one piece of equipment. Do not use a long, complex number or one that is subject to change. Instead, use a permanent number that may be easily seen when viewing the equipment. Also, remember to retire the Equipment ID number when you retire the equipment. |

Equip Rec # |

The system-defined, unique identifier for the piece of equipment. |

Equipment Type |

Specifies the category that further identifies this piece of equipment. |

Asset Class |

Sets the asset's class which is used to group together similar assets. The available list of classes come from records in the Asset Class Library that match this module. Setting an Asset Class for a record can enable extra functionality with Class specific Forms and System Assembly Components. |

*Required.

*Must be unique.

Purchase Date |

The date the equipment was purchased. |

Purchase Amount |

The dollar amount for which the equipment was purchased. |

Received Date |

The date on which the agency took possession of the equipment. |

Service Life |

The number of years that the equipment is expected to be used before being retired. |

Dep. Date |

The date on which the equipment will be depreciated or no longer used. This date is auto-calculated as: Purchase Date + Service Life = Depreciation Date. |

Salvage Value |

An estimate of the amount for which the equipment can be sold or salvaged. |

Dep. Amount |

The current worth of the equipment, which the system calculates as follows:

|

Book Value |

The current value of the equipment, which is calculated as: Purchase Amount - Depreciation Amount = Book Value |

Replace Cost |

The dollar amount necessary to replace the equipment. |

Hourly Rate |

The price of operating the item for one hour. This calculation is determined by adding all costs associated with a piece of equipment and dividing that sum by the total average hours: Total costs/Total Average Hours = Hourly Rate The system performs this calculation for all equipment with an operating status less than 950. |

Work Employee * |

Assigns the equipment to an Employee. The list of Employees comes from the Work > Administration > Work Flow Setup > Employee Setup module. Equipment assigned to an employee appears on the Issued tab of the selected Employee record. |

Plant ID |

Assigns the equipment to a Plant. The list of Plants comes from the Plant > Plant Inventory module. Note: The Equipment record is actually linked to a Plant Process record; however, the user must choose a Plant ID before identifying the related Process. |

Process |

Links the equipment to a Plant Process. The list of Processes comes from the Plant > Plant Process module. Note: The user must choose a Plant ID to select a related Process. |

Fleet ID |

Links the equipment to a particular Fleet vehicle. The list of vehicles comes from the Fleet > Fleet > Fleet Inventory. Note: This association can also be made in the Fleet Inventory using the Attached Equipment grid on the Tracking tab. |

Site ID |

Assigns the equipment to a specific Site. The list of Sites comes from the Facility > Site Inventory. Note: This association can also be made in the Site Inventory using the Equipment grid on the Equip/Fleet tab. |

Building ID |

Assigns the equipment to a specific Building. The list of Buildings comes from the Facility > Building Inventory. Note: This association can also be made in the Site Inventory using the Equipment grid on the Equip/Fleet tab. |

Floor ID |

Assigns the equipment to a specific Building Floor. The list of Floors comes from the Facility > Floors > Floor Inventory.

|

Room ID |

Assigns the equipment to a specific Building Room. The list of Rooms comes from the Facility > Rooms > Room Inventory.

|

Roof ID |

Assigns the equipment to a specific Building Roof. The list of Roofs comes from the Facility > Roofs > Roof Inventory.

|

WO Equip Code *

|

Links a record in the Equipment Inventory to a record in the Work Flow Setup > Equipment module. This function enables the piece of equipment to be used as a Resource on a Work Order, rather than as an Asset. (A Work Order Asset is the item that is being worked on. A Work Order Resource is an item being used to complete the Work Order.)

If the agency does not own the Work program, this field is not available. |

Vendor Rec # |

Indicates the vendor the equipment was purchased from. The list of Vendors comes from the Plant/Equipment > Warranties > Vendors module. More information about Vendors. |

Automated Gate ID |

Links the equipment to a record in the ITS > Automated Gate module. |

Camera Loc ID |

Links the equipment to a record in the ITS > Camera Locations module. |

DMS ID |

Links the equipment to a record in the ITS > DMS module. |

PDMS ID |

Links the equipment to a record in the ITS > PDMS module. |

Kiosk ID |

Links the equipment to a record in the ITS > Kiosk module. |

Pump House ID |

Links the equipment to a record in the ITS > Anti-Icing Pump House module. |

RWIS ID |

Links the equipment to a record in the ITS > Weather Station module. |

Sensor ID |

Links the equipment to a record in the ITS > Sensor module. |

Date Inspected |

Specifies the date the asset was last inspected. |

Pump Condition Motor Condition Seal Condition |

Describes the general condition of pump components, as observed during the most recent inspection.

|

Next Pump Insp Next Motor Insp Next Seal Insp |

Indicates the planned dates for the next inspections, which are based on the dates of the most recent inspections.

|

Operating Status |

Indicates the status of the asset (i.e., operational, out of service, sold).

|

Take Offline |

Indicates that the equipment is out of service. |

Parent Out of Service |

Indicates that the parent record associated with this Equipment record is out of service. |

Plant |

Indicates whether this Equipment item is currently linked to a Plant record. This relationship is configured in the Equipment record's Plant ID field. |

Facility |

Indicates whether this Equipment item is currently linked to a Facility record. This relationship is configured in the Equipment record's Site ID or Building ID fields. |

Fleet |

Indicates whether this Equipment item is currently linked to a Fleet record. This relationship is configured in the Equipment record's Fleet ID field. |

ITS |

Indicates whether this Equipment item is currently linked to an ITS record. This relationship is configured in the Equipment record's ITS field. |

MTBF Fields

The MTBF (mean time between failure) fields show the average time between instances that the equipment is out of service. Because equipment often must be taken out of service to be repaired or serviced, many manufacturers will provide an average MTBF (e.g., This pump must be serviced every four months.) Agencies can use Lucity to compare the Manufacturer's MTBF to the actual MTBF to determine whether the equipment is being serviced enough or is breaking down between scheduled maintenance.

MTBF |

Calculates the Mean Time Between Failure; that is, the average amount of time the equipment is operational between breakdowns. The system automatically calculates this field by:

|

Manuf MTBF |

Stores the manufacturer's expected Mean Time Between Failure, allowing an agency to determine whether the equipment needs to be replaced because it is failing more often than expected. |

Assigned To Email |

Specifies the email address of the person to whom the equipment is assigned. (An email address is required for Equipment Notifications.) |

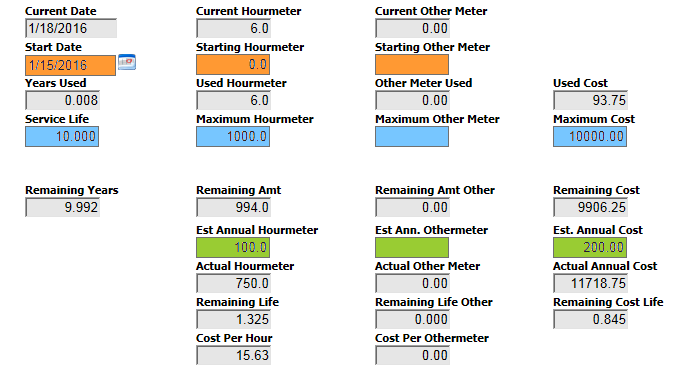

The Equipment module's evaluation fields help agencies estimate the running cost of its equipment. These fields can also be used to assess a piece of equipment's life span, based on running costs and recorded usage.

Users supply the data for certain evaluation fields (which appear in white in the module), while other fields are calculated automatically by the system (and are grayed out in the module).

User Populated Fields

The fields highlighted in color in the screenshot below must be populated by the user before the system can calculate values for other fields.

The following fields, highlighted in orange above, record information about the status of the equipment when it was put into service.

Start Date |

The date the equipment entered into service. |

Starting Hourmeter Starting Other Meter |

The meter reading when the equipment entered into service. |

The fields highlighted in blue above store data about the life-expectancy of the piece of equipment.

Service Life |

The number of years the equipment is expected to be in service. |

Maximum Hourmeter Maximum Other Meter |

The anticipated maximum meter reading for the equipment. |

Maximum Cost |

The maximum amount of money available to spend on equipment repairs and preventative maintenance during the equipment's life span. |

The fields highlighted in green predict the estimated annual usage of the equipment.

Est Annual Hourmeter Est Annual Other Meter |

The estimated annual meter reading for the equipment. |

Est Annual Cost |

The estimated annual expenses for the equipment. |

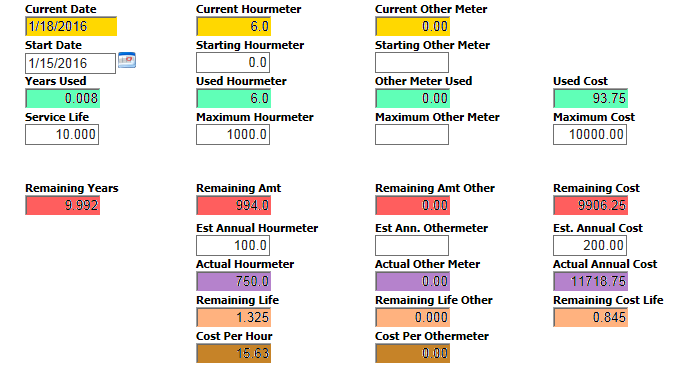

Calculated Fields

Once a user supplies the pertinent data and the record is saved, the system automatically calculates values for the remaining fields, which relate to the current state of the equipment. These system-calculated fields are highlighted in color in the screenshot below.

The data that the system uses to calculate these fields come from Meter Reading, Inspection, Work Order, and Reset records for the equipment. When the system detects that such a record has been created (that is, the record has a more recent date and higher meter reading), Lucity updates the system-calculated fields.

Lucity updates these values each night, as well as when a user saves or refreshes the Equipment record.

Current Amount |

|

Current Date |

The last date that any Work or a Meter Reading was recorded for the equipment. |

Current Hourmeter Current Other Meter |

The most recent meter reading, as reflected in an Inspection record, Readings record, or a Work Order. |

Amount Used |

|

Years Used |

The number of years the equipment has been in service. Calculated as: Current Amount Date - Starting Amount Date. |

Used Hourmeter Used Other Meter |

The number of hours the equipment has been used since being put into service. Calculated as: Current Amount Meter - Starting Amount Meter. |

Used Cost |

The total dollar amount spent on the equipment to date. This includes Work Order costs and any additional costs listed in the grids on the Cost tab. |

Remaining Amount |

|

Remaining Years |

The number of years left in the equipment's estimated maximum life span. Calculated as: Maximum Amount - Amount Used. |

Remaining Hourmeter Remaining Other Meter |

The number of working hours remaining in the equipment's estimated life span. Calculated as: Maximum Amount - Amount Used. |

Remaining Cost |

The dollar amount left in the budget for equipment repairs and maintenance. Calculated as: Maximum Amount Cost - the Amount Used Cost. |

Actual Annual Amount Used |

|

Actual Hourmeter Actual Other Meter |

The number of hours the equipment is used in a year. Calculated as: Amount Used Hourmeter / Amount Used Date or Year. |

Actual Cost |

The dollar amount spent to keep the equipment running during the course of a year. Calculated as: Amount Used Cost / Amount Used Date or Year. |

Approx Remaining Life Span |

|

Remaining Life (Hourmeter) Remaining Life Other |

An estimate of the number of additional years the equipment is expected to run. Calculated as: Remaining Amount Hourmeter or Other Meter / Actual Annual Amount Used Hourmeter or Other Meter. |

Remaining Cost Life |

The dollar amount remaining, per year, to keep the equipment working. Calculated as: Remaining Amount Cost / Actual Annual Amount Used Cost. |

Average Cost per Meter |

|

Average Cost Hour Average Cost Othermeter |

The cost to run the equipment for one iteration of the meter. For example, it costs $100 to run the equipment for one hour. Calculated as: Amount Used Cost / Amount Used Hourmeter or Other Meter. |

The following asset fields are related to Work Orders, PMs and/or Requests:

Default WO Cat *** |

Lets users establish a default Category for the Asset. When a Work Order is created for the Asset, the default Category and related asset information are imported into the new Work Order record. Multiple Categories are available in the pick-list. |

No WO/PM/REQ *** |

When enabled, users cannot create Work Orders, PMs, or Requests for that Asset. The Asset also no longer appears in the selection dialog boxes for WO/PM/Request modules. This function is useful for assets that are logged in Lucity, but have been retired. |

Asset Account # |

Indicates the reference number of the general account to be billed for any work done on the asset. The system can be configured to handle account numbers in various formats. The format dictates how users complete this field. More information about Account Number formats

|

Asset Proj No - Acct |

Indicates the reference number for a specific project account to be billed for any work done on the asset. The system can be configured to handle project account numbers in various formats. The format dictates how users complete this field. More information about Project Account Number formats

|

Maintenance Zone * |

Enables agencies to group Assets based on a location. The Maintenance Zone value is then carried over to the Work Order, where it can be used to automatically assign a Supervisor. This field is most easily populated through GIS. |

Alternate Zone * |

Enables users to group Assets based on a secondary location parameter of an agency's choosing. The Alternate Zone is then carried over to the Work Order. This field is most easily populated through GIS. |

WO Comment * |

Enables user to include information relevant to working on the asset. Information that a user enters here is copied to the Work Order > Asset > Asset Comment field. |

Last WO Task |

Displays the last date that asset was included on a work order. |

* Applies to PMs.

* Applies to Requests.

* Applies to Work Orders.

X Y Z |

Contains basic information about the assets location.

|

In Map |

Indicates that the record is found in the GIS system.

|

GIS Subtype |

Indicates which Subtype is used to classify the asset in GIS. |

GIS Needed |

Enables users to mark the record as needing to be added/updated in GIS. |