Equipment

Relationship

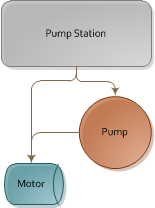

Pump Station

Parent to Pump and Motor

Pump

Dependent of Pump Station

Parent to Motor

Motor

Dependent of Pump Station and Pump

The Tracking tab consists of three grids: Parent, Dependents, and Equipment Status Tracking. The Parent and Dependents grids show the relationship between attached equipment pieces. The Status Tracking grid shows the current status or availability of the equipment piece.

Relationships and Operating Status

The Parent's operating status affects the status of the dependent. If the parent equipment is out of service, all of its dependents are also considered out of service.

In the following example, if the Pump Station goes out of service, the statuses of the associated Pump and Motor will be be changed to "Out of Service" as well.

Equipment |

Relationship |

|

Pump Station |

Parent to Pump and Motor |

|

Pump |

Dependent of Pump Station Parent to Motor |

|

Motor |

Dependent of Pump Station and Pump |

Parent Grid

The Parent grid is read-only. It shows any pieces of equipment to which this item has been attached. In other words, this grid will only display data if the current equipment record is listed as a dependent of another equipment record. (This relationship is also reflected in the other record's Dependents grid.)

A sample of the grid appears below. Sort records in the grid by clicking on the headings. An arrow (highlighted in orange below) indicates whether the data appears in ascending or descending order.

![]()

Dependent Grid

The Dependents grid links other equipment records to the current equipment record. For example, a pump installed in a pump station is, therefore, a dependent of the pump station.

Note: The same piece of equipment can be a dependent of multiple other pieces of equipment.

A sample of the grid appears below. Sort records in the grid by clicking on the headings. An arrow (highlighted in orange below) indicates whether the data appears in ascending or descending order. The functions in the grid allow the user to view, add, edit, or delete the record.

![]()

Equipment Status Tracking

The Equipment Status Tracking grid logs the status or availability of the equipment piece. Records either can be added manually to this grid, added automatically based on changes to the Operating Status field in the header, or added from the Work Order Asset grid by right-clicking on the record and choosing Change Asset Status.

A sample of the grid appears below.

![]()

How To Add an Equipment Status Record

How To Add an Equipment Status Record

MTBF fields

At the bottom right are the MTBF (Mean Time between Failure) fields. These help show the average time between instances that the equipment is out of service. Because equipment needs to be taken out of service to be repaired on a regular basis many manufacturers will provide an average MTBF. e.g. This pump must be serviced every 4 months. This Manufacturers expected MTBF can be compared to the actual MTBF to see if it is being serviced enough, or is breaking down between scheduled maintenance instances.

Field |

Function |

MTBF |

Automatically calculated to display the Mean Time Between Failure. This is calculated by:

|

Manuf MTBF |

Enter the manufacturer's expected Mean Time Between Failure. This allows an agency to determine whether the equipment needs to be replaced because it is failing more often than expected. |