Use Category Level Security

|

Enables administrators to control what types of work orders each employee can view and edit based on the Work Category of the work order. (For example, sewer employees need full access to Sewer records; however, they do not need full access to Water records.)

An administrator can set Category Level Security for the user In the Employee module. The admin can specify which security level each user has access to (Add/Edit/Delete, Edit Only, View Only, etc.) for each Work Category. Because the Category field is required, the employee is only able to edit work orders in the categories that he or she has rights.

Note: Each employee must have a Login ID defined in the Employee Setup module if this option is enabled.

Note: For more information on this security setting, see the Category Level Security topic in the Work Flow Setup > Employee module.

|

Automatically Associate Sub-Categories

|

In the Categories module, users can drag Tasks, Resources, Employees, Equipment, Materials, Fluids, Crews, and Problems into a category in the category tree. When this option is turned on, the system automatically associates any items dragged into the category with all of its related subcategories.

|

Disable Work Order Request Open Prompts

|

By default, when users create Work Orders from Requests, a system prompt asks them whether they would like to view the Work Order.

Check this option to disable the prompt and have the system automatically opens the Work Order. If this isn't checked, users will continue to be prompted to choose whether or not they wish to view the Work Order.

|

Validate Against Duplicate Asset/Task PMs

|

Warns users when there is more than one PM with the same Asset and Task combination.

|

Supervisor Manages Certifications

|

When enabled, only an employee's supervisor can add, edit, or delete the employee's record in the Employee grid on a Certification record. The system checks the supervisor's Login ID to ensure that he or she has access to the record.

|

Enable Timesheet Locking

|

Gives supervisors the ability to lock Timesheet records in the web application after they have been reviewed, thereby preventing anyone from editing, adding, or deleting any related Work Order Resource records. Users who attempt to edit or delete related Resource records will receive a series of warnings indicating that the resource is locked.

Note: For additional information on timesheet locking, see the Lucity Web help guide.

|

Force Use of Predefined Account Numbers

|

Validates all Account # fields in Work modules against a list of existing account numbers. Users may also select an existing account number from a list by clicking on the caption button for the field. This list is set up in Work > Work Flow Setup > Account Numbers.

|

Force Use of Predefined Account Project Numbers

|

Validates all Proj No - Acct fields in Work modules against a list of existing account project numbers. Users may also select an existing account project number from a list by clicking on the caption button for the field. This list is set up in Work > Work Flow Setup > Account Project Numbers.

|

Defer Task and Asset Calculations to Nightly Process

|

When a Work Order, Work Asset, or Work Task record is saved, the system performs several calculations. If a Work Order has many assets or tasks, these calculations can prolong the process of saving the record.

This control postpones the calculations so that they occur overnight, using Lucity Services, rather than at the time the record is closed. The benefit of this option is that large work orders are processed more efficiently, conserving network resources during peak work hours.

Note: Enabling this option means that the cost calculations for the work order may be inaccurate until that night or until a user runs one of the recalculation tools.

|

Department Specific Payroll Admins

|

Enables the Timesheet > Payroll Admin Management tool. This provides the ability to limit which users a payroll admin will see within the Timesheet Overview.

|

Automatically Calculate PO Total Amounts from Line Items

|

Automatically calculates a total for the Amount field on records in the Project Purchase Orders module using the Line Items records attached to the Purchase Order.

|

Automatically Calculate Invoice Total Amounts from Line Items

|

Automatically calculates a total for the Invoiced Amount field on records in the Project Invoices module using data from Invoice Details records attached to the invoice.

|

Recalculate Costs for All Project Management Records

|

Causes the Update Rollup Costs for Filterset tool in the Projects module and the Perform Cost Update tool in Project Tasks module to update all records that do not have the Inactive field marked. Normally, these tools would only update records with a Status < 950 and that are not marked Inactive.

|

Copy Location From Request to Work Order on Association

|

Causes Work Order and Work Request toolkits that associate work order and request records together to copy location an asset information from the request to the work order.

|

Integrate Work and Parts Inventory

|

Enables the link between the Work modules and the Parts modules. If this option is disabled, users cannot disperse Parts to work orders from the Inventory.

|

Always use Parts Default Location

|

Determines how the Parts Inventory disperses items to work orders. When enabled, the system assumes that the parts should be procured from the default location or from a mobile warehouse attached to the work order.

Note: The Default Parts Location is an area of the warehouse that is preselected in Parts Inventory to house a part.

|

Force Dispersal from Mobile Warehouses

|

Determines how the Parts Inventory disperses items to work orders. When enabled, the software assumes that parts should only be procured from the mobile warehouses attached to the work order.

Note: A mobile warehouse is a part warehouse that is linked to a work order Equipment record. The Equipment associated with the warehouse must be added to the work order as a Resource.

|

Prevent Negative Part Quantities

|

Prevents users from dispersing parts that are not in stock, which, in turn, prevents the parts inventory from tracking a negative quantity. If users try to disperse an inventory item (via work order) and the on-hand quantity is lower than the amount requested, they will receive a warning that the part could not be fully dispersed. Then, the system will adjust the part quantity specified to match the quantity currently available.

Note: To prevent individual locations from going negative use the Prevent Negative Part Quantities at Locations option.

|

Make Vendor Part No the Default for Part Lookup

|

Determines how the system looks up parts in the Purchase Orders module, the  PO Items dialog box in the Vendor module, or the Parts Inventory module. PO Items dialog box in the Vendor module, or the Parts Inventory module.

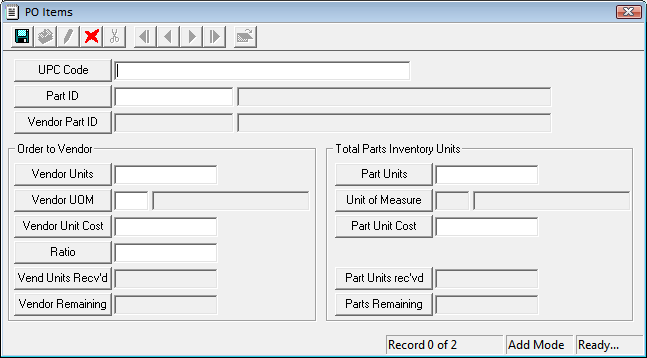

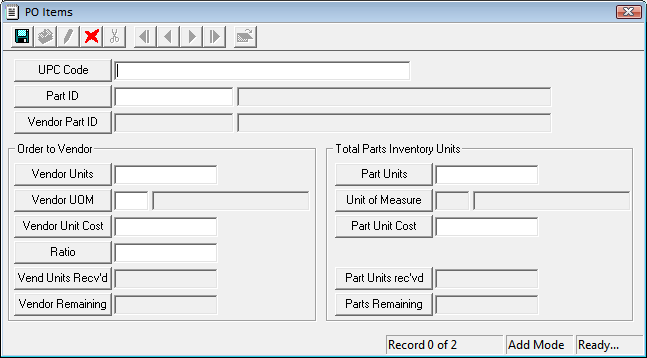

- Right-click in the grid and select Add Record. The following window appears:

- Select a Part using one of these methods:

- Enter the UPC Code - The system checks the Vendors > Vendor Parts grid for a part with the matching UPC Code. When it finds one, the system completes the Part ID and Vendor Part ID fields.

- Enter the Part ID** - The system checks the Vendors > Vendor Parts grid for a part with the matching Part ID. When it finds one, the system completes the Vendor Part ID and UPC Code fields.

- Enter the Vendor Part ID* - The system checks the Vendors > Vendor Parts grid for a part with the matching Vendor Part ID. When it finds one, the system completes the Part ID and UPC Code fields.

* The look-up method available is controlled by the integration option set in the Work Options module. If the Make Vendor Part No. the Default for Part Lookup option is set to Yes, the Vendor Part ID is the default look-up criterion. If it is set to No, the Part ID is the default criterion.

* If the Vendor listed in the PO is is marked as Restricted, then, only the parts associated with that vendor (via the Vendors module) are available in the Part ID pick list.

- Enter the vendor order information: units, price, etc. These are the order specs as indicated by the vendor.

- Enter the agency's part units and cost information. These fields differentiate the agency's part quantity/packaging and unit cost from those of the vendor.

- Save and close the record.

More information about PO Item records

- Checked - Users select a Vendor Part No from the pick list and the system enters the corresponding Part ID.

- Unchecked - Users select a Part ID from the pick list and the system enters the corresponding Vendor Part No. (if stored in the Vendor module).

|

Comma Delim list of UserIds that should not trigger disp/ret notif

|

Specifies which users should not trigger dispersal/return notifications when they disperse or return a part. To enable this option, supply a comma-delimited list of Lucity UserIDs (login IDs).

|

Email address to send dispersal/return notifications

|

Specifies an email address to notify every time a part is dispersed or returned.

|

Use Parts Warehouse Security

|

Enables the Security tab in the Warehouse module, which is used to control which users can access specific warehouses.

|

Use Part Open Inventory Date Range

|

Allows an administrator to specify a date range during which a part can be dispersed to a work order.

|

Prevent Negative Part Quantities at Locations

|

Prevents users from dispersing parts from a location that are not in stock at that location, which, in turn, prevents the parts inventory location from tracking a negative quantity. If users try to disperse an inventory item (via work order) and the on-hand quantity at a given location is lower than the amount requested, they will receive a warning that the part could not be fully dispersed. Then, the system will adjust the part quantity specified to match the quantity currently available.

To prevent the total quantity for the part to never go negative use the Prevent Negative Part Quantities option.

|

Eden Parts Integration

|

Enables the integration between the Lucity Parts Inventory and Eden Inventory Control.

|

Integration of Eden Financial Accounts

|

Enables the integration between the Lucity Work Order module and Eden General Ledger, Project Accounting, and Journal Entries.

|

Eden Account Number Levels

|

Configures how many levels/segments the agency uses for their Eden Account Numbers. This indicates the maximum number of segments allowed per account number.

|

Eden Project Number Levels

|

Configures how many levels/segments the agency uses for their Eden Project Numbers. This indicates the maximum number of segments allowed per project number.

|

Project Number Delimiter

|

Allows you to specify a character used to define different segments of the Project Number (e.g. dash or asterisk that separates each segment of the account number).

|

Account Number Delimiter

|

Allows you to specify a character used to define different segments of the Account Number (e.g. dash or asterisk that separates each segment of the account number).

|

Use Partial Defaulting for Accounts

|

When this option is enabled, agencies can use the Work Flow Setup modules to assign a default account number to each employee, task, and category that may be used in a work order. Then when a work order is created, the corresponding account numbers are combined (using the specified delimiter) to create one account number for the work order. For example, if you have a category account number of 1133, a main task account number of 0033, and an employee account number of 2233, the work order account number might resemble 1133-0033-2233. The length of the work order account number will depend on how many levels or segments you have specified in the Eden Account Number Levels option.

|

Use Partial Defaulting for Project Num

|

When this option is enabled, you can use the Work Flow Setup modules to assign a default project number to each employee, task, and category that may be used in a work order. Then when a work order is created, the corresponding project numbers are combined (using the specified delimiter) to create one project number for the work order. For example, if you have a category project number of 112, a main task account number of 212, and an employee account number of 312, the work order project number might resemble 112-212-312. The length of the work order project number will depend on how many levels or segments you have specified in the Eden Project Number Levels option.

|

Lock Processed WO Resources

|

Enable this to lock Work Order Resource records after they are processed by Eden. These records cannot be edited once locked.

|

Integration of Oracle e-Business Suite

|

|

Auto-Change WO Dates to Match Task Dates

|

Carries over the Start Date and End Date from the Work Order Task module to the Work Order module. This option helps ensure that work order records track the most recent date changes.

|

Populate Resource Dates from Task Dates

|

Carries over the Start Date and End Date from the WO Task module to the WO Resource module. Thus, every Resource (equipment, employee, etc.) has start and end dates that match the Task dates.

Note: This option could conflict with the Enforce Resource End Date = Start Date option if both options are enabled.

|

Enforce Resource End Date = Start Date

|

Ensures that the End Date and Start Date match on all WO Resource records. If a user attempts to enter dates that do not match, an error message appears.

Note: To conform to the requirements of most payroll systems, Lucity recommends that agencies restrict resources to one day only.

|

Reset Missed Starting Date

(A, P or N)

|

Ensures that the next Start Date for a PM is in the future, not the past, by setting the Next Start Date based on the date the work was actually performed, rather than the scheduled start date.

If work starts late on a PM, the system would normally maintain the established interval (e.g., one week), and set the Next PM date for one week from the previous End Date. However, that means that when a Start Date is missed, the next PM date could be in the past. This option resets the PM Start Date to the next available date in the future, according to the same interval.

For this option, an administrator can select Always, Prompt, or Never.

- Always - Turns the option on.

- Prompt - Asks the user if he or she wants to set the PMs Start Date to the next available date based on the same interval.

- Never - Turns the option off.

Note: This option only works for PMs that use Starting Date intervals (not the WO Ending date).

Example:

- A PM has a scheduling interval of one week. The previous Work Order was completed on 3/7/2014; so, the system scheduled the next PM for 3/14/2014. However, the crew was unable to complete the work order as scheduled, and, instead, completed it on 3/24/2014. If the Reset Missed Starting Date option is not enabled, the system would enforce the one week interval and schedule the next PM for 3/21/2014--a date in the past. With this option enabled, the system resets the next PM date to the next interval date available, i.e., 3/28/2014--a date in the future.

Note: If you have set this option to "P" for Prompt, and the PM is reset due to a work order imported from a field laptop, the start date will NOT be reset because the program cannot prompt for a user response.

|

Auto-Populate End Date from Start Date for Task/Resource

|

Automatically completes the End Date fields with the data from the Start Date fields in the WO Resources and Tasks modules. The system will not override an existing value.

|

Enforce Starting and Ending Dates on Close of Work Order

|

Requires users to enter a Start Date and End Date for the Work Order before they can close it.

|

Enforce Task End Date = Start Date

|

Requires that the Start Date and End Date match on each Task record.

|

Enforce Resource dates are within Task Start and End dates

|

Requires that the Start Date and End Date for all Resources fall on or within the Start Date and End Date for the related Task.

|

Always Generate Work orders on PM Schedule

|

Causes PMs to generate new work orders based on their schedule even if the previous work orders were not closed.

Note: This only affects PMs with a Starting Date schedule.

|

Default Work Order Start Time (HH:MM)

|

Enter what time work is usually started for the day.

- This is used to automatically fill out the Start Time field on work order (if the field isn't manually filled out).

- This is also used to calculate a work order Projected Completion Date.

|

Default Number of Hours worked per day

|

Enter the number of hours worked per day in your organization.

- This is overridden first by Hours per Day for the Leadworker or Supervisor.

- Second by the Hours per Day for the Crew.

|

Enter the Minimum Number of Linked WOs required to update the Est Duration

|

Enter how many work orders the program must have available as a sample when trying to calculate the amount of time it takes to complete that type of work.

- Used by the PM module's Calculate Average Duration from WOs toolkits.

- The toolkit will not update the PM's Est Duration (Hrs) field unless it has at least the entered number of linked work orders.

|

Address Block Range for WOs

|

Enables the user to set a numerical value indicating the address range of a block. This option works in conjunction with the special F8 search option available in the Work Order Location dialog box in Work Orders.

|

Populate WO Account Number from Main Task Number

|

Carries over the default Account Number defined in the Task Setup module for the main task to the Account Number field on the first tab of the Work Order module.

|

Carry Over Documents from PM to WO

|

Automatically attaches documents attached to the PM to any Work Order created from the PM.

|

Notify user when Asset is already attached to an open Work Order

|

Alerts users who attempt to create a Work Order for an Asset that an open work order already exists for that asset. This alert also appears when users attempt to attach such an asset to an existing work order.

|

Disable Work Order overdue notifications

|

Prevents the system from sending notifications for overdue work orders.

|

Use Start and End Times to Calculate Hour Units

|

Automatically updates the Work Order > Resource > Units field based on the values in the Start Date/Time and End Date/Times.

|

Populate Empty Task Supervisor with Main Supervisor

|

Copies the data in the Supervisor field on the Work Order record to the Task Supervisor field in the WO Task record.

Note: This option is applied only if there is no default Supervisor assigned in the WO Task module. This option will not override default data or data entered by the user.

|

Populate Empty Task Crew with Main Crew

|

Carries over data from the Assigned Crew field in the Work Order module to the Task Crew field in the WO Task module.

Note: This option is applied only if there is no default Crew assigned in the WO Task module. This option will not override default data or data entered by the user.

|

Populate Empty WO Task Account Number with Main number

|

Enables the user to set a default Account Number and Project Number in the main WO screen and copies that data to the empty Account Number and Project Number fields on the WO Task.

|

Prevent Task Deletion if Resource Attached

|

Prevents users from deleting any Work Order or Work Order Task records that have Resources attached. The Delete button and the Delete Record option in the right-click menu are not disabled. Instead, when a user attempts to delete such a record, a message appears to inform them that the selected Work Order or Task cannot be deleted.

|

Populate Resources from Crew

|

Carries over all Resources associated with the Crew selected in the WO Task record to the WO Resources record.

|

Populate Empty WO Resource Account Number with Task

|

Populates the empty Account Number and Project Number fields on the WO Resource record with the data from those fields on the WO Task record.

|

Use Fleet Readings from Fuelings on Close WO

|

Applies the current odometer reading from the Fleet module to an asset when a Fleet Work Order with a single asset is closed without an odometer reading. This makes sure the odometer reading is filled out on all Work Order Asset records for Fleet vehicles which in turn makes sure that any related PMs will get reset.

|

Max Past Days for Fueling Readings on Close WO

|

Related to the Use Fleet Readings from Fuelings option. This indicates the maximum number of days in the past the program will accept the vehicle's odometer reading as current when filling out the Work Order Asset's odometer reading.

The asset records odometer is only updated if the following are true:

- Fleet Current Date is more recent than Today's Date - [# of days specified in the setting].

- Fleet Current Date - [# of days specified in the setting] is more recent than Today's Date.

|

Disable Resource Availability Checking

|

Disables the function that checks whether a Work Order Resource is scheduled for the same time period on separate work orders. For information on this option, see the Resources Grid Special Functions topic.

|

Allow Alt Description After Resource

|

Lets users add an alternative description for a Work Order Resource and changes the <Tab> order to:

- Resource field

- Alt Description field

- Normal Units field (if it is 0 or null)

If No is selected, the <Tab> order is:

- Resource field

- Normal Units field (if it is 0 or null)

|

Integrate Fleet Warranty with WO Resources

|

Simplifies the process of adding new warranties to Fleet assets. This control is useful when a user replaces a part on a vehicle with a new part that has a warranty.

For this to work:

- The option must be enabled.

- Find the Work Flow Setup > Material record for the part and fill out the Warranty Length or Warranty Distance field.

- Add the material to the Work Order as a Resource and set the End Date.

- Right-click on the asset record and select Add Part Warranty to Vehicle.

- The system will automatically create a Fleet Warranty record based on the End Date and the Warranty Length or Warranty Distance. This warranty is then associated to the Fleet asset.

|

Populate Resources from Lead Worker

|

Automatically adds the Lead Worker as a Work Order Resource to every Task that is added in the Work Order > Task grid.

|

Prevent Duplicate Resources on Add Multiple

|

Stops a resource from being added to a Work Order more than once when using the Add Multiple Tools.

|

Maximum Number of Segments to Search

|

Limits the number of segments that the system searches and makes available to view when the Stretch function is used to add pipes to the Work Order > Asset grid. Limiting the scope of the search enables users to view results more quickly.

The default maximum number is 30. Users can change this limit in the General Options tab or on the individual Stretch screen.

Note: This function is applicable only to Sewer Pipe and Storm Conduit assets.

|

Copy Address from Asset

(A, P or N)

|

Enables users to insert addresses and XY coordinates for related assets in work orders. An administrator can select Always, Prompt, or Never.

- Always - The system will automatically try to insert an asset's address into the location grid.

- Prompt - When an asset is added to the WO Asset grid, the system asks the user whether or not to add an Address to the Location grid.

However, if Prompt is selected and the work order is generated from a PM, Request, or Create Work Order tool, the system does not automatically add the address to the Location grid.

- Never - The user must manually enter an address in the Location grid.

|

Allow Duplicate Assets per Work Order

|

Permits a single Asset to be added to the same Work Order multiple times.

|

Status Tracking

|

Enable to track changes to the Work Order Status field.

|

Category Change

|

Enable to track changes to the Work Order Category field.

|

Problem Change

|

Enable to track changes to the Work Order Problem field.

|

Resulting Work Creation

|

Enable to track changes to the Work Order Category field.

|

Assigned Crew Change

|

Enable to track changes to the Work Order Assigned Crew field.

|

Supervisor Change

|

Enable to track changes to the Work Order Supervisor field.

|

Sys ID Grid Delete

|

Enable to track when assets are deleted from the Work Order Asset grid.

|

Priority Change

|

Enable to track changes to the Work Order Priority field.

|

Task Change

|

Enable to track changes to the Work Order Task field.

|

Department Change

|

Enable to track changes to the Work Order Category field.

|

Leadworker Change

|

Enable to track changes to the Work Order Leadworker field.

|

PO Items dialog box in the Vendor module, or the Parts Inventory module.

PO Items dialog box in the Vendor module, or the Parts Inventory module.