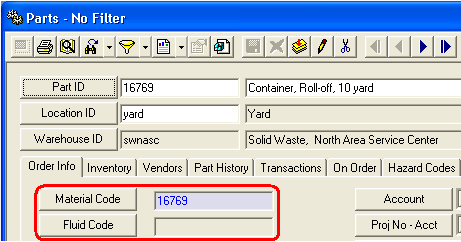

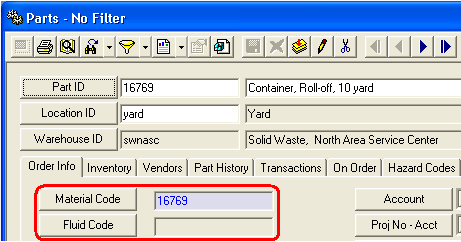

There are several integration options available; however, they only apply to materials and fluids that are linked to the Work Order modules (Standard, Lite, Daily Work) through the Parts Inventory module. Materials and fluids can be linked by assigning a material or fluid code in one of the following two fields in the Parts Inventory module.

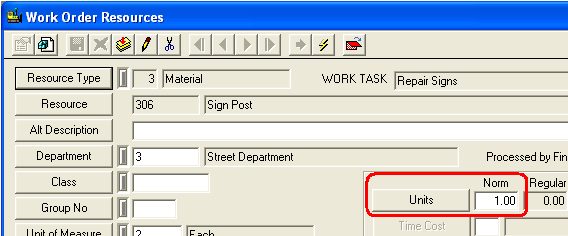

Also, the Units field in the Resources record must be populated for any of these integration options to work.

Reporting Section

Note: The Warehouse Status Detail and Summary Reports summarize the total monetary value of each warehouse based on the number of parts in inventory. These reports are only accurate when using the Average Cost or Fixed Cost costing methods. These costing methods set costs for all inventoried parts at the time new parts are received. Thus, all parts in a given warehouse have the same cost. Alternatively, with FIFO (First In First Out) or LIFO (Last In First Out) costing methods, the system has no way of determining what parts at what cost are in a given warehouse. Due to this costing difference, parts entered using FIFO or LIFO costing methods won't allow the system to calculate an overall monetary value for the warehouse as a whole. When you are using one of these costing methods, run the Parts Valuation Report for Avg/Fixed Cost and FIFO/LIFO in the Parts Inventory. These reports will provide a cost for the overall inventory.

Note: The Parts Valuation Report for Avg/Fixed Cost and FIFO/LIFO provide a cost for the overall inventory. To determine the total monetary value of each warehouse based on the number of parts in inventory, you can run the Warehouse Status Detail and Summary Reports in the Warehouse module. Note that the reports in the Warehouse module are only accurate for Average Cost or Fixed Cost costing methods. These costing methods set costs for all inventoried parts at the time new parts are received. Thus, all parts in a given warehouse have the same cost. Alternatively, with FIFO (First In First Out) or LIFO (Last In First Out) costing methods, the system has no way of determining what parts at what cost are in a given warehouse. Due to this costing difference, parts entered using FIFO or LIFO costing methods won't allow the system to calculate an overall monetary value for the warehouse as a whole.