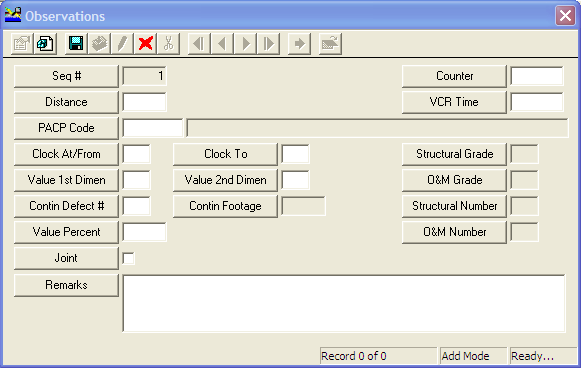

Observation Records store information about the condition of the conduit at a specific point in the conduit.

Field |

Function |

Seq # |

This denotes the order the observation was made in during the inspection. |

Distance * |

Enter the distance along the conduit the observation occurred at. |

Defect * |

Enter the type of defect/observation made at during the inspection. The defect chosen determines how the program calculates the rest of the fields. |

Counter |

Record the time into the video of the identified condition, in seconds. |

VCR Time |

Record the time into the video of the identified condition in HHMMSS format. Use 0 as a space holder. |

Clock At/From Clock To |

These fields are used to track observations that run along the circumference of a conduit. Use the Clock At/From field to enter the clock position where the defect starts. (like the face of a clock 1 o'clock, 4 o'clock) Follow the defect around clock-wise and use the Clock To field to mark the end of the defect. |

Value 1st Dimension |

Indicate the dimensions of defects to the nearest inch or millimeter. |

Value 2nd Dimension |

Used for intrusion of tap or width of non-circular connecting conduits to the nearest inch or millimeter. |

Continuous Defect # |

This field is used to mark that this is the beginning or end of a continuous defect. Continuous defects run along the length of a conduit. If this is the observation of the beginning of a defect enter an S in this field. If this is the end of the defect enter a F in this field. After the S or F enter a number to link the start and end of the defect. So one continuous defect's end points will match (ie S2, F2 or S6, F6) |

Value Percent |

Used to express the percentage value of a defect. For example if the defect is debris blocking the conduit, what percentage of the conduit is blocked? |

Joint |

Mark this checkbox to indicate a defect located near a joint. |

Structural Grade |

This is the grade of structural damage at the observation. This is automatically calculated by the system based on PACP Standards. It takes the Clock At/From, Clock To, and Value Percent fields into account for all Defects that are considered structural defects. |

O&M Grade |

This is the grade of O&M damage at the observation. This is automatically calculated by the system based on PACP Standards. It takes the Clock At/From, Clock To, and Value Percent fields into account for all Defects that are considered O&M defects. |

Structural Number |

The is the number of occurrences of the structural defect in this single observation. This will usually be 1. However, at the end of a continuous defect the system will automatically calculate a number of occurrences based on the length of the defect and the Default Length for Continuous Defect Calculation, Use Pipe Section Length when Available for Continuous Defect Calculation. |

O&M Number |

The is the number of occurrences of the O&M defect in this single observation. This will usually be 1. However, at the end of a continuous defect the system will automatically calculate a number of occurrences based on the length of the defect and the Default Length for Continuous Defect Calculation, Use Pipe Section Length when Available for Continuous Defect Calculation. |

* Required Field