Field Name

Use/Purpose

Task **

The user-generated ID and description for the task.

WO Task Code

Links the Rehab Work Task to a record in the Work Flow Setup>Tasks module.

- Press F9 to select an existing Work Task from the pick list and link the two records together.

- Press F5 to enter the Task code in this field. Doing so will create a new record in the Work Flow Setup>Tasks module for this Rehab Work Task. The Work Flow Setup record must be edited and made Active. (Tasks must be activated in order to be selected in the Work Order modules.)

Rehab Units

Indicates whether the Entire Pipe, Partial Pipe, or individual pipe sections (Each) are rehabilitated when this task is selected.

Rehab Class

Specifies a rehabilitation or repair classification for the task in this record. Sample Rehab Classes include Main Line Repair, Service Lateral Repair, and Line Cleaning.

% I/I Removed

Indicates the percent of infiltration and inflow to be removed when using this work task.

Min Rehab Length

Designates the minimum length of pipe to be repaired when a point defect is rehabbed. For example, if this field is set to "6," and a crack is repaired, then 3 feet of pipe should also be repaired on either side of the crack.

Pt Repair Min Dist

Designates a search distance for the Rehab task. When the Rehab task is selected for a point repair, the model searches the selected distance on either side of the point. If another defect is found within the specified distance, that defect is included in this repair, and the tool will then search again based on this distance. If a Min Rehab Length is set, the model takes that value into account before searching.

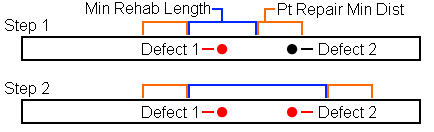

To illustrate:

In Step 1 below, the model selects Defect 1 for repair and plans to repair the area that falls within the Min Rehab Length (bracketed in blue). It then searches the pipe based on the Pt Repair Min Dist (bracketed in orange). During that search, the model finds Defect 2, which can be repaired using the same task.

In Step 2, the model selects Defect 2. It then extends the section to be repaired to include the area around Defect 2 based on the Min Rehab Length (blue). The system once again searches around the of area the pipe to be repaired based on the Pt Repair Min Dist. It finds no other defect; so, the process ends.