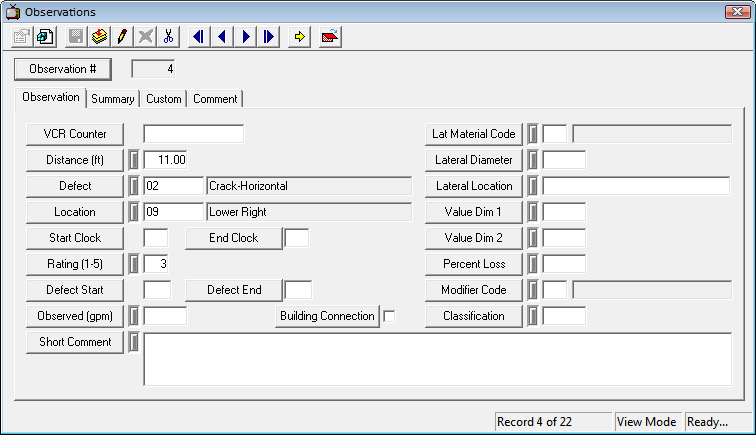

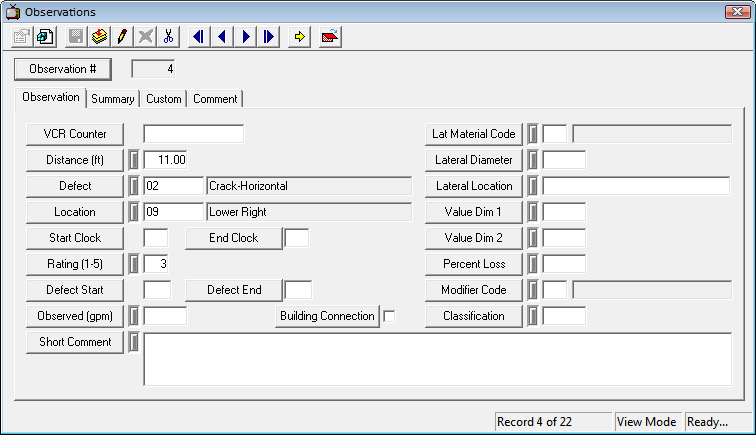

TV Observation records store information about items found during a TV inspection.

Header

The header fields contain general information to identify each observation. It appears at the top of the module window and remains visible as users navigate through the module's tabs.

Field |

Function |

Observation # |

This is the system-generated unique ID for the observation. |

Observation Tab

The Observation tab stores information about the type of observation, its location, and the extent of the defect.

Fields |

Function |

VCR Counter |

Number on the tape counter for the beginning of the observation. |

Distance (ft) * |

Distance from the starting point of the inspection to the location of the observation. |

Defect |

Type of defect/observation made during the inspection. |

Location |

Site of the observation. |

Start Clock End Clock |

Together, these fields track observations that run along the circumference of a pipe. Use the Start Clock field to enter the clock position where the defect starts. (as on the face of a clock: 1 o'clock, 4 o'clock, etc.) Follow the defect around clock-wise, and use the End Clock field to mark the end of the defect. |

Rating (1-5) |

Reflects the severity of the defect on a scale of 1-5, with 1 as the least severe and 5 as the most severe. |

Defect Start Defect End |

Indicate whether the observation is at the beginning or end of a continuous defect. Continuous defects run along the length of a pipe. The record for the beginning of a continuous defect is matched to the record for the end of the continuous defect by entering a matching ID into these fields. Example: If this is the observation of the beginning of a crack, enter CR1 in the Defect Start field. Then, create another observation record for the end of the defect and enter CR1 in the Defect End field. The system will match the two and summarize the defect information on the Summary tab. Note: Each Defect Start should have only one matching Defect End. |

Observed (gpm) |

Actual amount of infiltration and inflow (I/I) observed in the pipe due to the defect. Measured in gallons per minute. |

Building Connection |

Indicates whether the observation was at a connection to a building. Note: If the Defect record in the TV and Lamp/Infilt/Struct/Clean tabs of the Inspection Setup module is marked as a building connection, the system automatically marks this checkbox. |

* Required field.