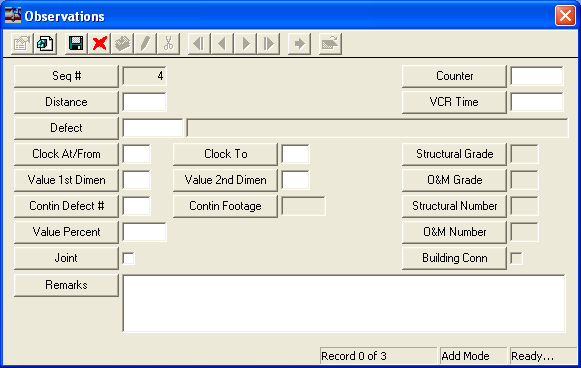

Observations records store information about the condition of the pipe at a specific point in the pipe.

Field |

Function |

Seq # |

Denotes the order in which the observation was made during the inspection. |

Distance * |

Indicates the distance along the pipe at which the observation occurred. |

Defect * |

Identifies the type of defect/observation made during the inspection. The type of defect chosen determines the rest of the fields that appear. |

Counter |

Indicates the time into the video of the identified condition, in seconds. |

VCR Time |

Indicates the time into the video of the identified condition in HHMMSS format. Use 0 as a space holder. |

Clock At/From Clock To |

Specifies the location of observations that run along the circumference of a pipe, as compared to positions on the face of a clock. Use the Clock At/From field to enter the clock position where the defect starts. Follow the defect around clock-wise and use the Clock To field to mark the end of the defect. |

Value 1st Dimension |

Records the dimensions of defects to the nearest inch or millimeter. |

Value 2nd Dimension |

Records the intrusion of tap or width of non-circular connecting pipes to the nearest inch or millimeter. |

Continuous Defect # |

Marks the beginning or end of a continuous defect. Continuous defects run along the length of a pipe. If this is the observation of the beginning of a defect, enter an S in this field. If this is the end of the defect enter an F in this field. After the S or F, enter a number to link the start and end of the defect so that one continuous defect's end points match (e.g., S2, F2 or S6, F6). |

Value Percent |

Expresses the percentage value of a defect. For example, if the defect is debris blocking the pipe, what percentage of the pipe is blocked? |

Joint |

Indicates a defect located near a joint. |

Structural Grade |

Specifies the grade of structural damage at the observation. This value is automatically calculated by the system based on PACP standards. It takes the Clock At/From, Clock To, and Value Percent fields into account for all Defects that are considered structural defects. |

O&M Grade |

Specifies the grade of O&M damage at the observation. This value is automatically calculated by the system based on PACP standards. It takes the Clock At/From, Clock To, and Value Percent fields into account for all Defects that are considered O&M defects. |

Structural Number |

Indicates the number of occurrences of the structural defect in this single observation. Usually, this value is 1. However, at the end of a continuous defect, the system automatically calculates the number of occurrences using the length of the defect and the Default Length for Continuous Defect Calculation when the Use Pipe Section Length when Available for Continuous Defect Calculation sewer option is selected. |

O&M Number |

Indicates the number of occurrences of the O&M defect in this single observation. Usually, this value is 1. However, at the end of a continuous defect, the system automatically calculates the number of occurrences using the length of the defect and the Default Length for Continuous Defect Calculation when the Use Pipe Section Length when Available for Continuous Defect Calculation sewer option is selected. |

Building Connection |

Indicates whether the Defect selected is actually a connection line coming into the pipe. This field is automatically completed. |

* Required field.