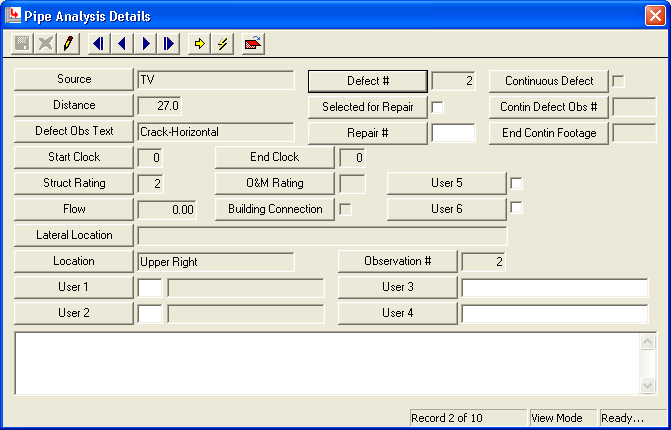

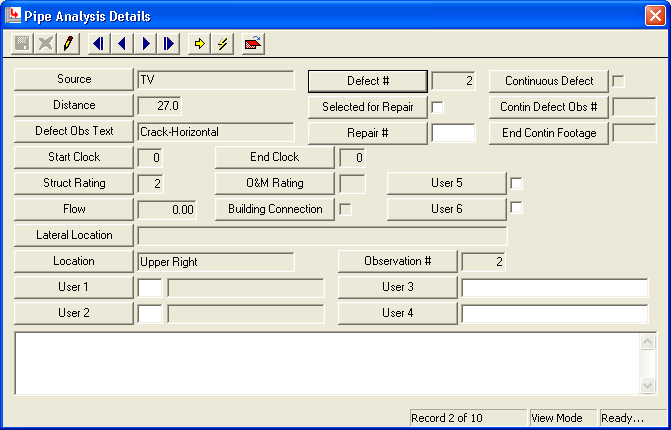

Pipe Defect records provide detailed information about each defect, as reported in the pipe's most recent inspection. An example appears below:

Field |

Function |

Source |

Indicates which Inspection module the defect came from. |

Distance |

Measures how far from the beginning of the inspection that the defect was found. |

Defect Obs Text |

Describes the defect. |

Defect # |

Displays the system-generated identifier for the defect. |

Selected for Repair |

Indicates whether the model found the defect to be in need of repair. |

Repair # |

Specifies which task in the Pipe Work Tasks grid will fix the defect. |

Continuous Defect |

Indicates whether this defect is part of a continuous defect. (More information about continuous defects may be found below.) |

Contin Defect Obs # |

Indicates where this observation falls along the length of the defect if it is part of a continuous defect. |

End Contin Footage |

Indicates the end footage for a continuous defect. |

Start Clock End Clock |

Specifies the location of observations that run along the circumference of a pipe, as compared to positions on face of a clock. Use the Start Clock field to enter the clock position where the defect starts. Follow the defect clockwise and use the End Clock field to mark the end of the defect. |

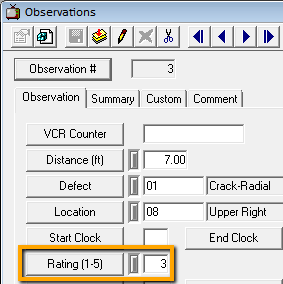

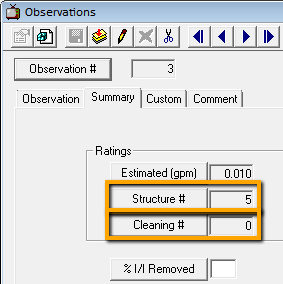

Struct Rating |

Indicates the Structural Rating found on the Inspection Observation record. (More information about pipe ratings may be found below.) |

O&M Rating |

Displays the O&M Rating found on the Inspection Observation record. (More information about pipe ratings may be found below.) |

Flow |

Specifies the amount of flow remaining after rehabilitation. |

Building Connection |

Indicates whether this observations is actually a connection to a building. |

Lateral Location |

Indicates the direction that the lateral enters the pipe. |

Location |

Specifies the site of the defect in the pipe. |

Observation |

Displays the system-generated, unique ID for the observation. |

Continuous Defects

Continuous defects are tracked in the Pipe Analysis Details dialog in the following manner:

Pipe Ratings

Pipe Ratings are recorded in the Pipe Analysis Details dialog as follows: